產品資訊

Full-pour system ( Hilex-C )

PU (POLYURETHANE) is a high polymer appeared in 1937. Since PU has superior characteristics, it’s suitable for athletic fields.■ Introduction:

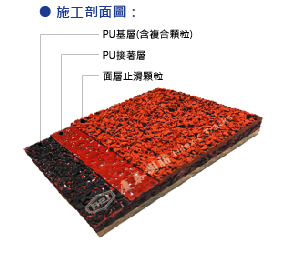

The base layer of Hilix-C full pu track is designed with sport field PU paving material mixed with composite granule or scattering composite granule immediately after applying sport field PU paving material. Repeat the steps above to achieve the required thickness, which can make the coat play the elasticity from the composite materials.

The design of the surface is made up of EPDM+PU to form a durable elastic layer. This high-performance elastic top layer combines with the softer elastic base layer to absorb and bear the impact from the athletes to play the elasticity. It better meets the requirement of the modern athletic fields.

■ Aapplication profile:

■ Physical properties:

| Testing Items | Quality | |

| (1) Specific gravity | Marked value ± 0.10 | |

| (2) Hardness(A) | 45~65 | |

| (3) Tensile strength (MPa) | 2.4 ↑ | |

| (4) Elongation (%) | 250 ↑ | |

| (5) Tear strength ( N/cm) | 98 ↑ | |

| (6) Compressive set (%) | 35 ↓ | |

| (7) Abrasion resistance (g) | 2.5 ↓ | |

| (8) Elasticity (%) | 30 ↑ | |

■ Application:

1.Confirm construction area

2.Fill all cracks & Surface preparation

3.Moisture measure

4.PU base layer (with composite granule)

5.PU base layer (with composite granule)

6.PU top layer

7.PU coating -> Embedded EPDM

8.Line Marking

■ Limitation:

1. Product should be kept away from ignition sources.

2. Provide adequate ventilation when applying this product in confined spaces or

stagnant air.

3. It is necessary to wear the protective gloves and glasses when applying this material.

4. Do not apply when the surface is not completely dry or relative humidity is above

85%.

5. Mix the main agent with hardener according to the designed mixing ratio.

6. Must have to follow the guidance while application.